Key components occupying 1 / 4 of the cost of 3.5-

Category:Industry News Source:Hongjia United Views:3666 Date:2019/12/7

Key components occupying 1 / 4 of the cost of 3.5-inch LCD screen! CF detection technology details, LCD hardware design must see

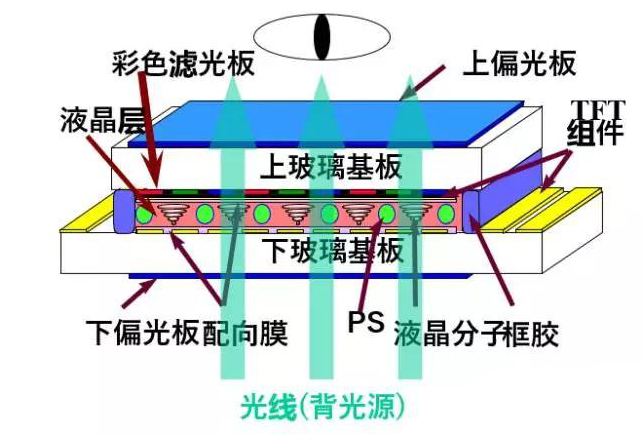

Our 3.5-inch LCD screen adopts the latest polarizer technology with a resolution of 480 * 800, supports RGB and Mipi interfaces, IPS full viewing angle and ultra-high definition retinal display technology. It is the latest upgrade of 320 * 480 3.5-inch LCD screen on the market. It is suitable for high-end product customers' high-definition and greasy display requirements of 3.5-inch LCD screen. It supports customization and long-term supply.

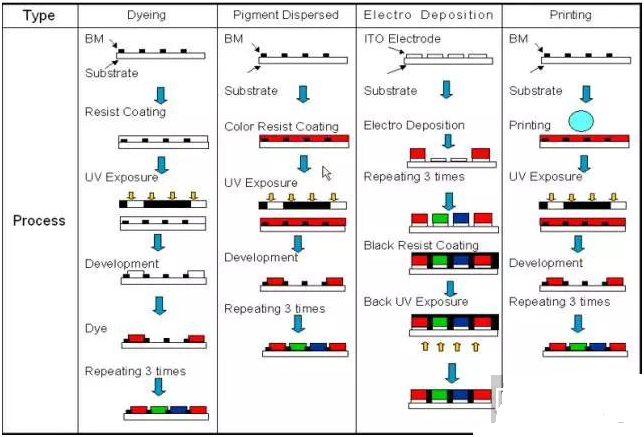

Color filter is the most important key component in the panel, accounting for about one quarter of the total manufacturing cost of the panel. The manufacturing method is to use red, green and blue photoresist raw materials on the plain glass substrate, and use yellow light etching or other technologies (such as pigment dispersion or transfer printing) to form a substrate with a long strip array of red, green and blue primary colors.

When the light source on the back penetrates the red, green and blue filters in each pixel and the liquid crystal driven by the circuit to present a gray scale, it will become a mixed light of three primary colors (RGB) with different proportions. The color image seen by the naked eye is the result of light passing through small liquid crystal lattices with filters into mixed light.

The so-called TFT panel manufacturing, in short, is the process of combining a color filter with a glass substrate with an active matrix, pasting polarizing plates on both sides, and adding a driving circuit and frame.

Types of CF

·Dye (staining)

·Dry film – 35kcf

·Pigment dispersion

CF process

1. Overview of division of labor

film

· BM/ITO sputter

· BM photo lithography

· BM etching

Huang Guang

· R/G/B photo lithography & cure

· Protrution (DD) photo lithography & cure、

· Photo-spacer (PS) photo-lithography & cure

testing

· Defect Inspection

· Final Inspection

· Repair

Basic steps of CF process

Positive photoresist process: the part of the photoresist illuminated by ultraviolet light will be removed in the subsequent development steps. For example: BM, DD

Negative photoresist process: the part of the photoresist that does not shine ultraviolet light will be removed in the subsequent development steps. For example: R, G, B, PS

CF制作流程图